This manual provides a comprehensive guide for the Lenze SMVector AC Tech drive, covering installation, operation, programming, and compliance with industrial standards․ It ensures safe and efficient usage․

Overview of the Lenze SMVector AC Tech Drive

The Lenze SMVector AC Tech Drive is a high-performance frequency inverter designed for controlling asynchronous motors, offering precise speed regulation and flexible operation․ It is suitable for integration into various industrial applications, providing reliable motor control․ The drive features a user-friendly local keypad and display, allowing operators to monitor and adjust settings directly․ With a robust design, it ensures efficient operation in diverse environments; The SMVector drive supports multiple control modes, including local and remote operation, and is compatible with additional I/O modules for enhanced functionality․ This drive is ideal for applications requiring high torque and dynamic performance, making it a versatile solution for industrial automation needs․

Key Features and Benefits of the SMVector Drive

The SMVector Drive offers high-performance motor control with advanced features such as adjustable frequency operation, efficient speed regulation, and flexible configuration options․ It provides precise torque control and compatibility with various motor types․ The drive includes a user-friendly interface with a local keypad and display, simplifying operation and programming․ Enhanced safety features ensure compliance with industrial standards, while its compact design allows for easy installation in diverse environments․ The SMVector Drive supports multiple control modes and integrates seamlessly with additional I/O modules, expanding its functionality․ Its robust construction ensures reliability in demanding applications, making it a versatile and efficient solution for industrial automation systems․ This drive is designed to optimize performance and reduce operational costs․

Purpose and Scope of the Manual

This manual is designed to provide detailed guidance for the installation, operation, and maintenance of the Lenze SMVector AC Tech drive․ It serves as a comprehensive resource for technicians, engineers, and users to ensure safe and efficient operation․ The manual covers technical specifications, safety guidelines, programming instructions, and troubleshooting procedures․ It also outlines compliance with local codes and regulations, ensuring adherence to industrial standards․ The purpose of this manual is to empower users with the knowledge needed to maximize the drive’s performance while minimizing risks․ By following the guidelines provided, users can achieve optimal functionality and longevity of the SMVector drive in various industrial applications․

Technical Specifications of the SMVector Drive

The SMVector drive operates at nominal output current, with specifications tailored for industrial environments; Performance metrics, temperature limits, and environmental requirements are detailed to ensure optimal operation and reliability․

Electrical Ratings and Performance Metrics

The SMVector drive is designed to operate at a nominal output current, ensuring high efficiency and reliability in industrial applications․ Electrical ratings include voltage, current, and frequency specifications, tailored for optimal performance across various motor types․ Performance metrics such as power factor, overload capacity, and thermal limits are clearly defined to ensure safe and efficient operation․ These specifications enable the drive to handle diverse industrial demands while maintaining precision control over motor speed and torque․

Detailed technical data, including maximum output current and operating frequency ranges, are provided to assist users in selecting the appropriate drive for their specific application․ These metrics ensure the SMVector drive meets industrial standards for performance and reliability․

Environmental Operating Requirements

The Lenze SMVector AC Tech drive is designed to operate in standard industrial environments, with specified temperature and humidity ranges to ensure optimal performance․ The drive should be installed in areas with ambient temperatures between 0°C and 40°C and humidity levels not exceeding 90% without condensation․ It is not recommended to expose the drive to direct sunlight, corrosive substances, or explosive atmospheres unless specific explosion-proof configurations are applied․ Proper ventilation should be maintained to prevent overheating․ Compliance with local environmental regulations and standards is mandatory to ensure safe and reliable operation․ These requirements are essential for maintaining the drive’s efficiency and longevity in various industrial settings․

Output Current and Temperature Limits

The Lenze SMVector drive operates within defined output current and temperature limits to ensure reliability and longevity․ The nominal output current (I_n) is specified in the ratings table, suitable for most industrial applications․ However, in certain conditions, the output current or temperature may need to be limited to prevent overheating or damage․ Exceeding these limits can result in reduced performance or drive malfunction․ It is crucial to monitor these parameters, especially in high-load or extreme environmental conditions․ For specific combinations or unique applications, consulting Lenze AC Tech support is recommended to ensure optimal operation within safe boundaries․ Proper management of these limits ensures efficient and safe drive performance․

Safety Guidelines and Compliance

Adhere to local codes and regulations, which take precedence over manual recommendations․ Ensure explosion-proof motor considerations are met for hazardous environments․ Always follow proper safety protocols․

General Safety Precautions

Always ensure proper grounding of the SMVector drive to prevent electrical shock․ Wear protective gear when handling electrical components․ Avoid operating the drive in hazardous environments without proper certification․ Never bypass safety features or attempt repairs without disconnecting power․ Ensure all personnel are trained in safe operating procedures․ Regularly inspect cables and connections for damage․ Follow all warnings and cautions outlined in the manual to maintain a safe working environment․ Compliance with local codes and regulations is mandatory․ Failure to adhere to safety guidelines may result in equipment damage or personal injury․ Proper safety practices are essential for reliable operation and system longevity․ Always refer to the manual for specific precautions․

Local Codes and Regulations

Compliance with local codes and regulations is mandatory when installing and operating the SMVector drive․ These codes take precedence over the recommendations provided in the manual․ Ensure all installations adhere to national and regional electrical standards․ The SMVector drive is designed as a component for integration into larger systems, and its use must comply with applicable industrial and safety regulations․ Always consult local authorities to verify specific requirements․ Failure to comply may result in legal consequences or operational hazards․ Lenze AC Tech assumes no liability for non-compliance with local regulations․ Proper adherence ensures safe and reliable operation of the drive within any regulatory framework․ Regulatory compliance is essential for system integrity and user safety․

Explosion-Proof Motor Considerations

The Lenze SMVector drive is not inherently explosion-proof and must not be used in hazardous environments without proper safeguards․ If integrating the drive with an explosion-proof motor, ensure all components meet relevant explosion-proof standards․ Lenze AC Tech does not warrant its products for use in explosion-proof applications, and such use is at the customer’s own risk․ Proper installation and compliance with explosion-proof motor requirements are essential to prevent risks; Always consult local regulations and Lenze technical support for specific guidance․ Additional protective measures may be necessary to ensure safe operation in explosive environments․ Failure to comply can result in serious safety hazards․ Explosion-proof motor configurations require careful planning and adherence to specialized safety protocols․

Installation and Setup

Proper installation and wiring are crucial for safe operation․ Use the local keypad for initial configuration and ensure environmental conditions meet specifications for optimal performance․

Mounting Requirements for the Drive

The Lenze SMVector AC Tech drive must be mounted vertically to ensure proper cooling and prevent damage․ Use the provided mounting holes and ensure the surface is flat and sturdy; Maintain a minimum spacing of 10mm from adjacent equipment to allow adequate airflow․ For panel mounting, secure the drive firmly to avoid vibration․ Ground the drive chassis to ensure electrical safety․ Avoid exposing the drive to direct sunlight or moisture․ Follow all local codes and regulations for installation․ Proper mounting is essential for reliable operation and to prevent premature wear․ Always refer to the manual for specific torque specifications and installation guidelines․

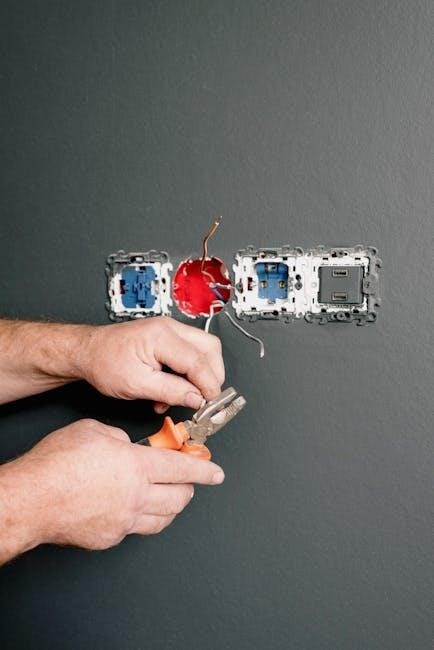

Wiring Guidelines and Connections

Proper wiring is critical for safe and reliable operation of the Lenze SMVector AC Tech drive․ Use appropriately rated cables for power and control connections, ensuring compliance with local electrical codes․ Connect the motor and power supply as specified in the manual to avoid damage․ Secure all connections tightly, following the recommended torque specifications for terminals․ Keep power and control wiring separated to minimize interference․ Ground the drive according to local regulations to ensure electrical safety․ Use shielded cables for sensitive control signals to prevent noise interference․ Verify all connections before powering up the drive․ Improper wiring can lead to malfunctions or safety hazards․ Always double-check connections for accuracy and integrity․

Initial Configuration Steps

Begin by powering up the SMVector drive and ensuring all connections are secure․ Use the local keypad to navigate to the parameter menu by pressing the Mode (M) button․ Enter the motor’s nameplate values, such as rated voltage and frequency, to ensure proper operation․ Set the maximum speed (P100) and enable digital inputs if required․ Save the configuration by exiting the menu․ Verify the drive’s functionality by testing the START/STOP and Rotation (R/F) buttons․ Ensure all safety features are enabled and alarms are configured․ Refer to the manual for default parameter settings and adjustments․ Proper initial setup ensures reliable performance and prevents potential issues during operation․

Operating the SMVector Drive

The SMVector drive is controlled via a local keypad and display․ Key functions include START/STOP, rotation direction, and mode selection for parameter access․ Use Up/Down buttons to navigate and adjust settings․ The CTRL button (on 15HP models) enables specific start modes․ Ensure all safety precautions are followed during operation․

Control Inputs and Functional Overview

The SMVector drive operates through a user-friendly control interface, featuring a local keypad and display․ The START/STOP button controls motor operation, while the Rotation (R/F) button sets the direction․ The Mode (M) button toggles between operational and parameter modes․ Up/Down buttons navigate and adjust parameter values, enabling precise control․ The CTRL button on 15HP models selects specific start modes․ Digital inputs can be configured for positive or negative logic, allowing customization of system behavior․ This intuitive design ensures efficient operation and easy parameter configuration, making the SMVector drive versatile for various industrial applications while maintaining safety and performance standards․

Local Keypad Functions and Navigation

The SMVector drive features a local keypad with intuitive navigation for seamless operation․ The START/STOP button initiates or halts motor operation, while the Rotation (R/F) button selects the motor’s direction․ The Mode (M) button switches between operational and parameter modes, allowing access to advanced settings․ The Up/Down arrows enable easy navigation through parameter menus and adjustment of values․ Additionally, the CTRL button on 15HP models provides further control options․ The keypad’s display offers clear feedback, ensuring users can monitor and adjust settings efficiently․ This user-friendly design simplifies operation and configuration, making it easy to optimize the drive’s performance for specific applications while adhering to safety and operational guidelines․

START/STOP, Rotation, and Mode Buttons

The SMVector drive’s control panel includes essential buttons for straightforward operation․ The START/STOP button powers the drive on/off, initiating or halting motor operation․ The Rotation (R/F) button toggles the motor’s direction, allowing forward or reverse operation․ The Mode (M) button switches between operational and parameter modes, enabling access to advanced settings․ LEDs provide visual feedback for status and active modes․ These buttons are designed for intuitive control, ensuring quick and precise adjustments․ The CTRL button, available on 15HP models, offers additional functionality for enhanced control․ Together, these buttons streamline operation, making it easy to manage the drive’s performance and configuration efficiently․

Up/Down and CTRL Button Operations

The Up and Down buttons are essential for navigating the SMVector drive’s menu and adjusting parameter values․ Pressing Up increases the selected parameter’s value, while Down decreases it․ These buttons allow precise control during configuration․ The CTRL button, available on 15HP models, provides additional functionality, enabling quick access to specific features․ Used together, these buttons simplify parameter adjustments and menu navigation, ensuring efficient setup and operation․ Proper use of these controls is key to optimizing the drive’s performance and achieving desired operational outcomes․ Always refer to the manual for detailed instructions on their use in different operational modes․

Programming and Parameter Settings

Program the SMVector drive by entering the parameter menu, adjusting values, and configuring digital inputs․ This section details how to customize settings for optimal performance․

Entering and Navigating the Parameter Menu

To access the parameter menu, press the Mode (M) button on the local keypad․ The display will show “P000,” indicating the start of the parameter menu․ Use the Up/Down arrows to scroll through parameters, with each press moving to the next or previous parameter․ Parameter numbers and descriptions are displayed for easy identification․ Press the Mode button again to exit the menu․ Always refer to the manual for specific parameter details and ensure changes are saved properly to maintain drive functionality․ This process allows users to customize settings for optimal performance․ Proper navigation ensures accurate configuration of the SMVector drive․

Adjusting Parameter Values

To modify parameter values, navigate to the desired parameter using the Up/Down buttons․ Once the parameter is selected, press the Mode button to enter edit mode․ Use the Up/Down buttons to adjust the value, ensuring it aligns with the drive’s operational requirements․ After making changes, press the Mode button again to save and exit edit mode․ Some parameters may require a manual reset or power cycle to take effect․ Always refer to the manual for specific parameter limits and configurations to avoid improper settings․ Proper adjustment ensures optimal performance and safety of the SMVector drive in various applications․ Parameter adjustments should be done cautiously to maintain system integrity․

Configuring Digital Inputs and Logic

Configuring digital inputs and logic on the Lenze SMVector drive involves setting up the inputs to control specific functions․ Access the parameter menu using the Mode button and navigate to the digital input configuration parameter, typically P100 or P101․ Use the Up/Down buttons to select the desired input and function․ Choose between positive or negative logic for each input, depending on the wiring of your sensors or switches․ Assign each input to a specific function, such as starting/stopping the motor or enabling a mode․ Save your settings by pressing the Mode button again․ Some configurations may require a drive reset or power cycle to take effect․ Ensure settings comply with local codes and regulations, as they take precedence over manufacturer recommendations․ Proper configuration ensures seamless integration and operation of the SMVector drive in your system․ Always test the configuration to confirm functionality․

Additional I/O Modules and Accessories

Enhance functionality with ALSV01 v1․0, ESVZAL0, and ESVZAL1 modules, compatible with NEMA 1 and 4X inverters, ensuring seamless integration and expanded system capabilities․

ALSV01 v1․0 Additional I/O Module

The ALSV01 v1․0 module expands the SMVector drive’s functionality by providing additional digital inputs and outputs․ Designed for seamless integration, it enhances system control and flexibility․ Compatible with NEMA 1 and 4X inverters, this module supports advanced configurations․ It allows for custom logic setups, enabling tailored solutions for specific applications․ Installation is straightforward, with clear guidelines ensuring proper connection and operation․ The module includes LED indicators for status monitoring, simplifying troubleshooting․ Compliance with local codes and regulations is essential, as specified in the manual․ This accessory is ideal for users requiring expanded I/O capabilities to meet demanding industrial requirements․

ESVZAL0 and ESVZAL1 Configurations

The ESVZAL0 and ESVZAL1 configurations are additional I/O modules designed for the Lenze SMVector drive, offering enhanced functionality and flexibility․ These modules provide supplementary inputs and outputs, enabling advanced control logic and system integration․ They are compatible with both NEMA 1 and NEMA 4X inverters, ensuring versatility across various industrial applications․ The configurations support custom setups, allowing users to tailor the drive’s behavior to specific requirements․ Installation and configuration follow straightforward guidelines, ensuring seamless integration․ These modules are ideal for applications requiring expanded control capabilities, while maintaining compliance with local codes and regulations․ They enhance the drive’s adaptability to meet diverse operational needs․

Compatibility with NEMA 1 and NEMA 4X Inverters

The Lenze SMVector drive is fully compatible with both NEMA 1 and NEMA 4X inverters, ensuring reliable performance in diverse industrial environments․ NEMA 1 inverters are suitable for general-purpose applications, while NEMA 4X inverters are designed for more demanding conditions, offering resistance to dust and water ingress․ This compatibility allows the SMVector drive to be integrated into a wide range of systems, providing flexibility for different operational requirements․ The drive meets the necessary standards for both configurations, ensuring optimal performance and durability․ This versatility makes the SMVector drive a robust choice for various industrial applications, from standard to harsh environments․ Proper installation and setup are essential to maintain compliance and functionality․

Maintenance and Troubleshooting

Regular maintenance ensures optimal performance․ Check for dust, clean filters, and inspect connections․ Common faults include overheating or power issues․ Refer to diagnostic codes and reset manually if needed․

Routine Maintenance Requirements

The SMVector drive requires regular maintenance to ensure optimal performance and longevity․ Check and clean internal and external filters to maintain proper airflow and prevent overheating․ Inspect all electrical connections for tightness and signs of wear, ensuring reliable operation․ Clean the drive periodically to remove dust and debris that may affect cooling efficiency․ Check fan and cable condition for any visible damage or wear․ Update firmware as needed to access the latest features and improvements․ Review parameter settings to ensure they align with the application requirements․ Verify environmental conditions comply with specified operating limits․ Adhere to Lenze’s recommended maintenance schedule for uninterrupted functionality and to prevent unexpected downtime․ Use only genuine Lenze parts for replacements to maintain warranty validity and performance standards․

Common Faults and Diagnostic Procedures

The SMVector drive may encounter faults such as overtemperature, output current overload, or communication errors․ Overtemperature faults often result from high ambient temperatures, blocked airflow, or excessive load․ Check and clean cooling systems and ensure environmental conditions are within specified limits․ For output current overloads, verify load requirements and adjust parameters to match the application․ Communication errors may stem from faulty connections or incorrect settings; inspect cables and ensure proper configuration․ Fault codes provide specific diagnostic insights, allowing targeted troubleshooting․ Consult the fault history via the parameter menu (P500) to identify recurring issues․ Reset faults manually after addressing the root cause to resume operation․ Refer to Lenze’s troubleshooting guide for detailed procedures and solutions to minimize downtime and ensure reliable performance․

Manual Reset and Fault History Checks

After addressing a fault, a manual reset is required to resume operation․ Access the parameter menu via the local keypad, navigate to Fault History (P500) using the Up/Down buttons, and review recorded faults․ Select the reset option to clear the fault state․ Ensure all safety precautions are followed before restarting․ Fault codes provide specific diagnostic information, aiding in identifying and resolving issues․ Refer to the troubleshooting guide for detailed procedures․ Always verify system stability after reset to prevent recurring faults․ Log fault history for maintenance records and future diagnostics․ Lenze AC Tech support is available for additional assistance․

Warranty and Support Information

Lenze AC Tech products are sold without warranty of fitness for a particular purpose․ Customer support is available for inquiries and technical assistance through specified channels․

Lenze AC Tech Warranty Policy

The Lenze AC Tech warranty policy does not include a warranty of fitness for a particular purpose or suitability for use with explosion-proof motors․ The company assumes no responsibility for direct, incidental, or consequential losses arising from the use of its products․ Users are advised to review the warranty terms carefully, as all products are sold “as is․” Any claims regarding defects or incompleteness must be reported immediately․ The manual and its content are subject to change without notice, and Lenze AC Tech disclaims liability for any errors or omissions in the documentation․

Customer Support and Service Contacts

For assistance with the Lenze SMVector drive, customers can contact Lenze AC Tech through various channels․ The service team is available at 508 278-9100 for technical support and repairs․ Sales inquiries can be directed to 800 217-9100․ Additionally, the official website provides access to downloadable resources, including manuals and technical documentation․ Users can also visit the online store for purchasing additional modules or accessories․ For repair services, the Lenze repair portal offers convenient options for submitting requests․ All contact information and resources are designed to ensure prompt and efficient support for SMVector users, addressing their needs effectively․

Repair and Replacement Options

For repairs, contact Lenze AC Tech at 508 278-9100․ Their repair portal streamlines service requests․ Replacement parts are available through authorized distributors․ The warranty doesn’t cover misuse or non-compliance with manual guidelines․ Repairs must be done by Lenze-authorized technicians to maintain warranty validity․ Visit www․lenze-actech․com for more details․

Additional Resources

Visit Lenze official website for SMVector PDF manuals, online store, and technical documentation․ These resources provide comprehensive support and updates for optimal drive performance and maintenance․

Downloadable PDF Manuals and Guides

The Lenze SMVector AC Tech manual and related guides are available for download as PDFs from the official Lenze website or authorized distributors․ These resources include detailed user manuals, troubleshooting guides, and technical specifications to ensure optimal drive performance․ The PDF manuals provide in-depth information on installation, configuration, and maintenance procedures․ Additionally, supplementary guides offer insights into parameter settings, I/O module configurations, and compliance with safety standards․ Users can access these documents by visiting the Lenze online store or contacting customer support․ Regular updates and revisions are published online, ensuring users have the latest information for their SMVector drives․

Online Store and Purchase Options

The Lenze SMVector AC Tech products and accessories can be purchased through the official Lenze online store or authorized distributors․ The online store offers a user-friendly interface for selecting and purchasing drives, I/O modules, and related accessories․ Customers can search by product code or description and view detailed specifications before placing an order․ Secure payment options and worldwide shipping are available․ Additionally, the online store provides access to promotional offers and discounted bundles for bulk purchases; For assistance, customers can contact the sales team via phone or email․ The online store ensures a seamless and efficient purchasing experience for SMVector drive solutions․

Technical Documentation and Updates

The Lenze SMVector AC Tech manual and related technical documentation are available for download on the official Lenze website․ Users can access PDF versions of the manual, technical notes, and application guides․ Regular updates ensure compatibility with the latest firmware and software releases․ The documentation includes detailed instructions for installation, configuration, and troubleshooting․ Additionally, Lenze provides online resources such as FAQs and technical bulletins to assist users․ For the most up-to-date information, visit the Lenze AC Tech website or contact their technical support team․ Regularly checking for updates ensures optimal performance and compliance with the latest industry standards․

Leave a Reply

You must be logged in to post a comment.